When it comes to training, many organizations try to save time and money by running workers through nearly identical technical programs. Unfortunately, this approach rarely delivers the kind of learning necessary to drive long-term change. Successful organizations understand that there are multiple types of learners, each with their own needs. If your organization is serious about upskilling its workforce, you need to invest the time to create a training program that provides tailored learning journeys to match the variety of different roles, responsibilities, and learning styles of individuals within your organization.

6 Essential Steps to Develop a Successful Technical Training Plan

When creating an industrial training program, these strategies should be top of mind.

1. Review Orientation and Safety Training

Use the first phase of your industrial training to review your organization’s safety essentials. This should cover all corporate and regulatory standards, including plant operations and safety protocols, as well as any emergency procedures and compliance standards. Be sure to mandate participation from all your technicians, regardless of their skill level.

Remember that orientation and safety training can still be tailored to the specific roles and responsibilities of the individual. In a power plant, for instance, there are diverse roles, each requiring specific safety training.

Safety training for control room operators could focus on the operational aspects of the power plant and include managing control systems, responding to system alerts, and executing emergency shutdown procedures. Training should include simulation-based exercises to mimic real-life scenarios, enhancing their decision-making skills in critical situations.

Maintenance technicians, responsible for the upkeep of power plant equipment, require safety training tailored to their exposure to high-voltage machinery and hazardous materials. Key areas of their training should include electrical safety, lockout/tagout procedures, and the correct use of personal protective equipment. Regular hands-on workshops are crucial, allowing technicians to apply safety principles in real-life scenarios.

2. Cover All Relevant Skills

When creating a curriculum for craft skills, it is important to tailor training to the specific needs of various craft positions. Each craft role, such as electrician, welder, or carpenter, requires a unique set of skills and knowledge. Your curriculum should include a wide array of courses that cater to these distinct skill sets. For example, electricians would need courses focused on electrical systems and safety, while welders would benefit from training in welding techniques and metallurgy. This role-specific approach ensures that craft workers are equipped with the precise skills they need to excel in their specific trade, enhancing both individual and organizational effectiveness.

3. Build Varying Levels of Complexity

Effective learning builds over time. When creating your curriculum, structure it in a way that advances logically, allowing learners to build from simple to more advanced concepts as they move forward through courses.

For example, when creating a training course for oil refinery instrumentation and electrical (I&E) technicians, trainees would start with the fundamentals of electrical systems and basic instrumentation used in an oil refinery. This includes understanding electrical safety, basic circuitry, and standard refinery instruments. The course would then progress to more complex electrical concepts and instrumentation diagnostics, such as advanced electrical components, process control systems, and troubleshooting common instrument issues. At the most advanced level, the training could involve in-depth study of refinery-specific control systems, complex electrical configurations, and advanced diagnostic techniques. Trainees would engage in real-world scenarios, like managing system outages or optimizing instrument performance, to apply their advanced knowledge in practical settings.

4. Assess Your Workers’ Skill Levels

Not all employees operate at the same level. It is important to assess the skills, knowledge, and competencies of each of your technicians. Use a combination of tests, interviews, and skills evaluations to determine what type of operator training each technician requires.

In the context of craft skills, recognize that technicians have varying levels of expertise. By assessing each technician’s skills, knowledge, and competencies you can customize training programs that meet their specific needs. Utilizing a mix of assessments such as practical tests, interviews, and skill evaluations can help identify each technician’s proficiency level. This approach ensures that all your operators, mechanics, instrument technicians, welders and other craft professionals receive training that fills their particular skill gaps and builds upon their existing competencies, leading to a more skilled and efficient workforce.

5. Adopt a Tiered Approach to Technical Training

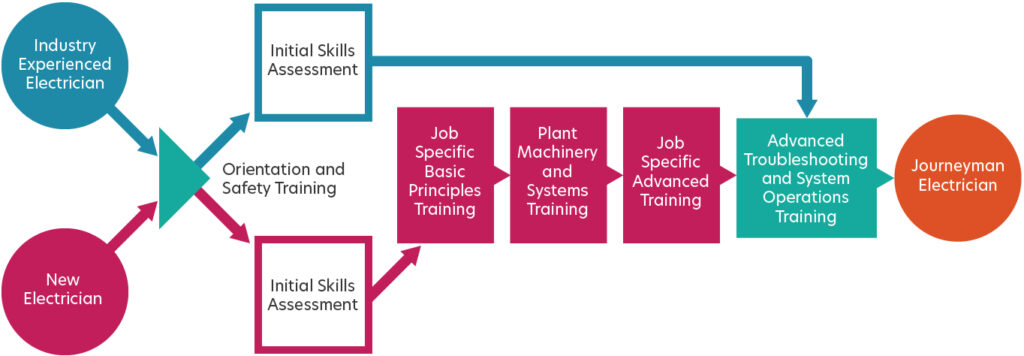

Using identical skills training courses can waste valuable time and frustrate individuals at a more advanced level of their careers. Create a tiered approach to learning with each level building on previous lessons. Then, use your assessment data to start everyone’s training at the tier matching their current knowledge and experience. This will connect learners at each level with what they need to know, while avoiding unnecessary repetition.

Build Learning Paths to Fit Your Learners

6. Integrate Hands-On Experiences

Balancing hands-on training with theoretical learning is essential for effective skill development in various roles at any facility. By utilizing specialized training stations (or industrial training aids), employees can practically apply theoretical knowledge gained in classroom settings. Stations focused on electrical troubleshooting, process control, power transmission, and hydraulics/pneumatics offer immersive experiences where employees engage in real-world tasks.

This approach solidifies their understanding of theoretical concepts and enhances their practical skills, ensuring they are well-prepared for the demands of their roles. Building synergy between hands-on and theoretical learning fosters a more comprehensive and effective training program. It drives problem-solving and critical thinking skills, which are vital in technical fields where technicians must regularly deal with ambiguity.

How Blended Learning Can Improve Your Learning Experience

No two individuals learn alike. To truly connect with its audience, industrial training should adopt a blended approach to learning, which utilizes a mixture of different techniques, tools, and content to help employees learn faster and more efficiently. When building your curriculum keep the following things in mind:

- Use a range of training methods, including online training materials, microlearning, lab sessions, and three-dimensional exploratory models to accommodate various learning preferences.

- Conduct face-to-face sessions led by an instructor who can facilitate discussions and address learner questions.

- These help you track their progress and tailor the learning experience to individual needs.

- Provide your learners with feedback on their progress through written comments, one-on-one discussions, and/or group meetings.

- Ensure that learning materials are accessible on a variety of devices and platforms. This will allow workers to learn anytime, anywhere.

- Regularly update your learning content to keep up with all technological and industry advancements.

Investing in Technical Training is Cost-Effective

At the beginning of this article, we mentioned how many companies use identical programs for their entire technical staff. While this approach may promise upfront savings, the savings quickly break down when lessons fail to connect with their audience. Ineffective curriculums often lead to repeat training—which incurs additional cost—and longer time to proficiency.

It is also important to factor in the enormous cost resulting from worker errors and accidents. If your technicians fail to learn the skills they need, mistakes will happen. This can lead to safety issues, regulatory noncompliance, and equipment downtime, which can open you up to potential lawsuits and have grave repercussions for your budget and reputation. Training should never be an afterthought; it is what makes or breaks the performance of your workforce.

Reach out to us if you would like to discuss your goals and build a training program that provides technicians the resources they need to perform at their best.